Cable equipment industry market development

Release time: 2021-12-31 18:01

(I) Analysis of future market development of cable and other equipment

According to the State Grid Corporation's "11th Five-Year Plan" period power grid planning and 2020 vision goal report, "11th Five-Year Plan" period, State Grid Corporation will add 330 kV or above power transmission lines 60,000 kilometers, substation capacity of 300 million kva, investment of about 900 billion yuan. By 2010, the trans-regional power transmission capacity will reach more than 40 million kilowatts and transfer more than 180 billion kilowatt-hours of electricity. During the 11th Five-Year Plan period, the average annual investment of State Grid Company is 180 billion yuan. Considering that the investment of China Southern Grid Company is generally 1/3 ~ 1/4 of that of State Grid Company, the total investment of State Grid and China Southern Grid Company may reach 225 billion yuan, which is a 90% increase compared with the Tenth Five-Year Plan period. Electrical equipment and power transmission and transformation equipment industry is facing relatively bright prospects for development. We consult experts believe that our transformer industry has two main development directions: one is to high voltage, ultra-high voltage direction, especially 750 kV, 1100 kV. The second is to energy conservation, small development direction, the former is mainly used in long-distance transmission and transformation lines, the latter is mainly used in urban transmission and transformation lines. Distribution transformer market capacity is large, but due to low technical barriers, numerous manufacturers, small enterprise scale, low industry concentration, market competition is still very fierce. But overall, distribution transformer industry development opportunities outweigh difficulties. China Business Information Network Company estimates that by 2010, China's dry-type transformer demand will reach 50 million kVA.

China's annual installed power generation capacity is more than 30GW, and the corresponding transformer new capacity is a multiple of the installed power generation capacity, the past is generally believed to be 11 times, now can reach 13 times, even more than, that is to say, the annual output of transformers to more than 400GVA, according to the analysis of China Electrical Equipment Industry Association, In 2007, the transformer is expected to complete 600GVA, with a year-on-year growth of 9%. In recent years, the capital for the construction and renovation of China's power grid has exceeded 100 billion yuan every year, and the electrical equipment used in the power station project, such as power plant equipment, booster station equipment, protection and monitoring equipment, generally accounts for 16% ~ 20% of the investment in power station equipment.

(II) Future market technology development direction of transmission and distribution equipment

At present, the transmission and distribution system is facing some new problems, such as the degree of environmental constraints will be more and more great, because of the electromagnetic interference, noise, electrostatic induction and landscape coordination problems that may be generated by high-voltage and ultra-high-voltage transmission lines and substations, the construction land required for new transmission lines and substations is also limited, etc. Due to the imbalance of energy distribution and economic development, large capacity long-distance transmission still has a strong momentum of development. The great benefit of power grid interconnection makes the trend of large power grid interconnection and transnational network transmission developing. The reform of power system marketization is gradually implemented worldwide, and the demand of power users for higher and higher power quality (anti-flicker, harmonics reduction), etc.

This requires that the transmission and distribution system has good environmental performance, high reliability, high power quality and flexible control of the power flow, and requires that the transmission and distribution equipment can adapt to the new characteristics of the future power system and meet the new requirements of the power system. The development trend of transmission and distribution technology is as follows:

1. In order to realize long-distance and large-capacity transmission, the voltage level of AC power transmission has been gradually increased. In the late 1960s, the AC power transmission voltage has been increased to 735kV, 765kV and 800kV, and many countries have built 345kV, 400kV, 500kV and 750kV. 800kV power grid.

2. HVDC technology develops rapidly. The main advantages of HVDC technology are: it is suitable for long-distance transmission without increasing the short-circuit capacity of the system; It is convenient to realize the non-synchronous network operation of two power systems and the network of power systems with different frequencies. The power modulation of DC system can improve the damping of power system, restrain low frequency oscillation, and improve the transmission capacity of parallel AC transmission lines.

The cost of DC transmission lines is lower than that of AC transmission lines, but the cost of converter stations is much higher than that of AC substations. It is generally believed that the overhead line is more than 600 ~ 800km, cable line is more than 40 ~ 60km, DC transmission is more economical than AC transmission. With the development of high voltage and large capacity thyristor and control and protection technology, the cost of converter equipment is gradually reduced, and the development of DC power transmission is rapid in recent years.

From the 11th Five-Year Plan to 2020, more than ten new HVDC transmission projects are planned. Two-end DC transmission has been a relatively mature technology in foreign countries. Moreover, multi-terminal DC transmission technology has been developed, and now there are three terminal DC transmission in operation in Canada. In addition, light DC power transmission is also developing, and it has been studied and applied abroad (ABB called HVDCLight, Siemens called HVDCPlus). Light DC transmission system, it uses GTO, IGBT and other turn-off devices to form the converter, save the converter transformer, the whole converter station can be moved, can make medium capacity DC transmission projects in a short transmission distance can also compete with AC power transmission. In addition, the converter can be made up of switchable devices. Because of the use of switchable power electronic devices, the problem of commutation failure can be eliminated. There is no requirement on the capacity of the receiver system, so it can be used to supply power to isolated small systems (offshore oil platforms, islands), and in the future, it can also be used for urban distribution systems. And is used to access the fuel cell, photovoltaic power generation (PhotovoltaicPowerGeneration) distributed power supply.

At present, the converter station equipment of the domestic UHVDC transmission project is mainly provided by ABB and Siemens, and the domestic XD company has introduced technology and carried out localization work. Now there are more new HVDC transmission lines, which requires speeding up the process of HVDC transmission equipment localization.

3. About Flexible AC Transmission System Technology (FACTS)

Flexible AC transmission technology (also known as flexible AC transmission technology) is based on power electronics technology and modern control technology to AC transmission system impedance, voltage, phase of the implementation of flexible and rapid adjustment of the transmission technology, can improve the AC transmission system controllability, transmission capacity and stability.

Flexible AC transmission system technology (FACTS) is an outgrowth of the "second Silicon revolution" in power system control technology. With the development of power grid and the operation of large-scale interconnected power network, the need of power flow and stability control and the progress of power electronics technology have greatly promoted the development and application of a new transmission technology, flexible AC transmission system technology.

4. Compact transmission technology. The compact transmission technology reduces the distance between phases of the transmission lines and changes the arrangement, thus reducing the reactance of the lines, increasing the capacitive reactance, and increasing the rated natural power under the condition that the rated voltage of the lines remains unchanged. This is a relatively economic transmission technology to improve the ultra-high voltage AC transmission capacity. In 1999, a 500kV compact test transmission line (Changping -- Fangshan) was built in North China, 85km long, with six-split sub-conductors (such as 6x240mmz), 750mm diameter of the ring, inverted triangle arrangement between phases, 6.7m distance between phases, 10m distance between the conductor and the ground, 16m width of the corridor. The natural power of a compact transmission line is 1/3 higher than that of a conventional line. A shunt reactor should be installed at an appropriate position of the line, and the capacity of the reactor should be controllable, so that the reactive power flow of the system can be dynamically balanced according to the load changes of the line, and the dynamic stability of the grid can be guaranteed. The controllable reactor used in this compact transmission line is the key equipment that needs to be produced independently.

5. Large-capacity power transmission and distribution equipment

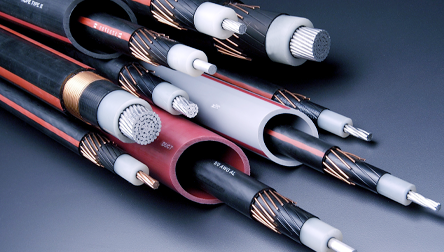

Large capacity transmission and distribution equipment mainly include: large capacity transformer refers to 500kV, l000MVA or above transformers, mainly in order to adapt to the power supply needs of large load center, save the land used by the substation, at present, the load intensive East China, Nanjing power grid has been used in succession of this 500kV, 1000MVA large capacity transformer. Large section cable, such as 220kV, 2500mm2 power cable; Development and application of high section overhead conductors and high section heat resistant conductors above 2x630m.mz. Manufacturing of circuit breakers with breaking capacity of 63kA and above.

6. Gas Insulated Transmission Line (GIL)

SF6 gas insulated transmission lines have a larger transmission capacity than cable transmission lines, can be laid on the ground and underground, and the cost is lower than cable lines. At present, some major transmission and distribution manufacturers in the world have developed gas insulated transmission lines.

7. High temperature superconducting power transmission is promising

A high temperature superconductivity project between the U.S. Department of Energy and Southern Wire is a 100ft(lft=0.3048m), 3-phase power cable system. The next decade will be a decade of market development and material industrialization for high temperature superconductivity (including generators, transformers, motors, cables, etc.). The world superconductivity market is forecast to reach US $30 billion/year in 2010 and US $244 billion/year in 2020.

8. Highly integrated, compact and intelligent transmission and distribution equipment

The most representative types of compact transmission and distribution equipment are gas-insulated switchgear (GIS) used in high-voltage and ultra-high-voltage systems, open-type combined switchgear, and gas-filled cabinet (C-GIS) and gas-filled ring cabinet used in medium-voltage systems. In order to meet the development needs of miniaturization and automation of modern substations, highly integrated and compact transmission and distribution equipment has emerged that combines primary equipment (such as circuit breakers, isolation switches, ground switches, current and voltage transformers, lightning arresters, etc.) and secondary equipment (intelligent protection, measurement and monitoring systems), such as ABB's PASS system. Siemens HIS system, etc. High voltage generator with cable winding (stator) has been developed abroad (known as Powerformer abroad, the output voltage of this kind of generator is 132kV or higher, the output voltage of the current conventional large capacity generator is 20kV), so that the power can be sent out without booster transformer, greatly simplifying the booster station of the power plant. The converter station equipment and flexible AC transmission equipment are also the perfect integration of high-voltage and ultra-high-voltage large-capacity electric energy conversion, control and digital monitoring technology. In the automatic monitoring system of modern power system, each transmission and distribution equipment on the equipment level will become the terminal equipment of the computer monitoring system, and realize the information exchange between the substation interval layer, the station control layer and the network management. High reliability, maintenance-free, intelligentization, communication, online monitoring and remote fault diagnosis of transmission and distribution equipment will be the development trend.

9. New flexible and reliable intelligent power distribution system

The future power distribution system can provide high-quality "flexible", "reliable", "agile" and "perfect" electric energy services according to the needs of different users. Users are also free to choose the quality, type and supplier of electricity. The system has a perfect distribution power supply and energy storage system to ensure uninterrupted power supply; Perfect demand side management and real-time two-way transmission of information and so on. At present, distribution management automation system (DMS) is a very fast developing field, including distribution system SCADA, load control, automatic fault isolation, automatic reactive power compensation, power management and equipment management.

10. Pay attention to the environmental performance of power transmission and distribution equipment

We should pay attention to the environmental performance of the product, especially to use less SF6 gas (because SF6 gas will produce greenhouse effect), foreign countries have begun to use nitrogen, part of nitrogen and part of the SF6 gas mixture to replace SF6 gas and other programs. Contactors and other contacts do not use silver pick alloy (that is, silver oxidation pick, AgCdO, now abroad has used silver tin oxide, AgSnO2 instead) and other problems. The Directive on End-of-Life Electronic and Electrical Equipment and the Directive on the Restriction of the Use of Certain Hazardous Substances in Electronic and Electrical Equipment clearly require from 1 July 2006 to ensure that new electronic and electrical equipment placed on the market does not include six hazardous substances: lead, mercury, pick, hexavalent chromium, polyaustralidiphenyl (PBB) and polyaustralidiphenyl (PBDE). Therefore, in the contact materials of low-voltage appliances and relays where the use of brocade, such as silver oxide blessing, should be gradually used without pick components of the contact.

Related News